As one does about this time of year, ETQ has once again taken out its crystal ball to peer into the upcoming new year to identify the trends, behaviors and events that will shape how manufacturers perceive and interact with technology as a means to support their overall enterprise-wide quality goals.

It comes as no surprise that generative AI appears to be the frontrunner in just about every prognosticator’s predictions this year. Large language models, such as ChatGPT and Google Baird, democratized AI in one fell swoop in 2023. It’s everywhere: generative AI became a key bone of contention in the SAG-AFTRA writer’s strike, as well as a key issue for policy-making in the Biden administration and among legislators across the country.

From the enterprise, to the classroom, the White House to the production studio, AI is being used, tested, discussed and regulated. In the new year, it also will increasingly play a role on the manufacturing floor, bolstering enterprise-wide quality. In 2024, manufacturers will increasingly work to determine how to fit AI into their tech stacks, how to govern it and empower it as a key quality driver. Forrester predicts that GenAI “will be the fulcrum that businesses rely on to enhance, empower, and engage employees and customers.” Further, according to Gartner, “Generative AI (GenAI) is becoming democratized by the confluence of massively pretrained models, cloud computing and open source, making these models accessible to workers worldwide.” Gartner predicts that by 2026, more than 80 percent of enterprises will have used generative AI models and/or deployed it in production environments, up from less than five percent in early 2023.

When it comes to GenAI’s role in quality, ETQ predicts that manufacturers of all sizes will leverage it to produce user manuals, employee training guides, or to create compelling marketing messages for better customer engagement. It also will be used to help design products, or identify new supply chain partners for specific components. In these and other use cases, GenAI will begin to be explored as a productivity tool that empowers all members of the manufacturing enterprise, yet it will always play a supporting role, not replacing workers but giving them more time to focus on quality.

In addition to the rising role of artificial intelligence, ETQ sees four key trends shaping the new year for the manufacturing industry.

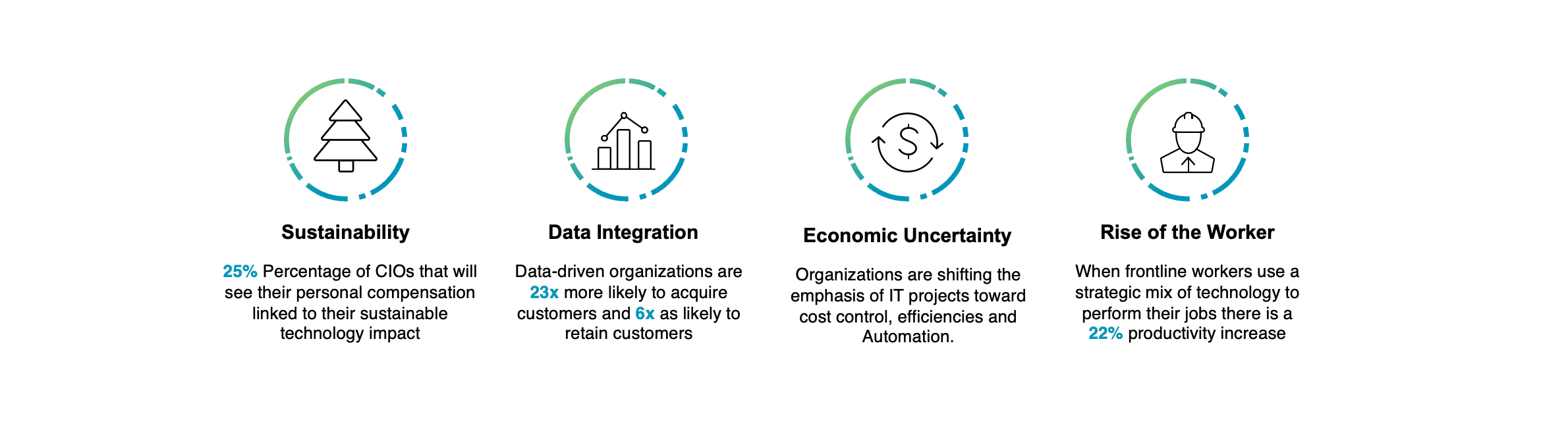

Data integration. Manufacturers have been able to successfully gather and analyze data within various departments for several years now. They’re generating and collecting more data than ever before, yet this data is often stored in a variety of different systems and repositories, making it difficult to access and manage. In 2024 the promise of a unified view of data from key sources across the enterprise becomes a reality, making data more visible and actionable enterprise-wide. This will be made possible thanks to open systems that enable easier integration via application programming interfaces (APIs), cloud-native systems accessible from anywhere and centralized systems that enable more seamless sharing and storing of data. According to McKinsey Global Institute, data-driven organizations are 23 times more likely to acquire customers, and six times as likely to retain customers than those that are not.

Rise of the worker. According to Deloitte, organizations can achieve tangible benefits by elevating the frontline worker’s digital experience and empowering their frontline workforce with the technology, tools, and information required for the job.” The firm estimates that when frontline workers are provided a thoughtful and strategic mix of technology to perform their jobs, productivity increases on average by 22 percent.” In 2024 we can expect to see greater empowerment of warehouse and plant personnel thanks to digital tools that enable them to do their jobs safer and more efficiently. In 2023, there remains a clear demarcation between the data and automation created in the warehouse and that which is gathered and shared across other areas of the business. In 2024, there will be greater integration of information between the connected worker, quality teams and other business functions, to create a connected quality ecosystem that flows seamlessly across the enterprise and out to suppliers.

Sustainability. Manufacturers have been talking about their commitment to sustainability for several years now, but 2024 will be when they take a more concerted effort to put it into action. This focus will be driven by their own corporate commitment, but also by rising regulations intended to reduce carbon emissions, switch to environmentally friendly sources of power and enable greater transparency into how products are sourced. Additionally, as the cloud, AI and the Internet of Things continues to grow, there will be rising concerns about their energy consumption and environmental impact. In fact, Gartner predicts that by 2027, 25% of CIOs will see their personal compensation linked to their sustainable technology impact.

Economic uncertainty looms. In 2024, companies will continue to focus on reining in costs and remaining profitable. Every digital initiative they undertake will need to show proven ROI and profitability before costly investment is put into its deployment. According to Gartner analyst, David Lovelock in a CIO Dive story, “Organizations are shifting the emphasis of IT projects toward cost control, efficiencies and automation, while curtailing IT initiatives that will take longer to deliver returns.” Based on this sentiment, manufacturers will realize that quality is one area where investment is crucial and that the price of poor quality is too high for taking a cost-cutting approach.

Mark Twain once said, “Prediction is difficult, especially when it involves the future.” At the outset of 2023, while many predicted that AI would become a major new tool for digital transformation, no one predicted the extreme buzz and ubiquity generative AI would create everywhere. As we enter 2024, we can expect the manufacturing industry to increasingly rely on intelligent tools and enterprise-wide data to enable a new level of quality, but along with it, we can expected to see a rise of the connected worker, leveraging new tools and technologies to enable safer environments, more productive and sustainable workplaces and seamless synergies across the manufacturing ecosystem.

What are your predictions for the new year? We’d love to hear your thoughts. Please reach out to info@etq.com.