Keynote Transcript beginning at:33:28

Lesson 2: As you know very well, manufacturing for us is not only the industry that we work within—where we supply our tools— but we are a manufacturer ourselves. So, we spend the best part of our time staying true to the promise of quality when we deliver our own devices to yourselves our customers

So, you can imagine the amount of work that went on during the pandemic when shortages and logistic nightmares pushed our teams to try and re-engineer and reassemble, and redesign our own supply chains. And the effort that has gone into onboarding new suppliers and building a quality culture within this ever-changing supply chain. This is something, that I believe you can relate to; something that is pretty much pertinent to what has happened throughout the industry.

One of the primary challenges, if you want to stay true to your brand promise and you want to stand behind the promise of quality, is to share that type of mindset and that quality vision with your ecosystem. Build an ecosystem that is just resilient and adaptable. This is true for us it’s true across the industries, such as electronics. Why do we relate to Apple? Why is the Apple brand so inspirational? Yes, it’s got to do with super cool gadgets and devices, but it’s also got to do with the experience. The way we experience all those applications, all of that software, and the fact that Apple is super-focused on making sure that the quality that is provided across those partners and developers is spotless.

35:57:00

Think of the world of OEMs, automotive OEMS, 15 to 20 years ago 50% of the value chain was staying within the supply chain. As of today, that probably is closer to 80 to 85% which means that super aspirational brands like the one on the screen heavily rely on their suppliers to help them deliver on their quality promise.

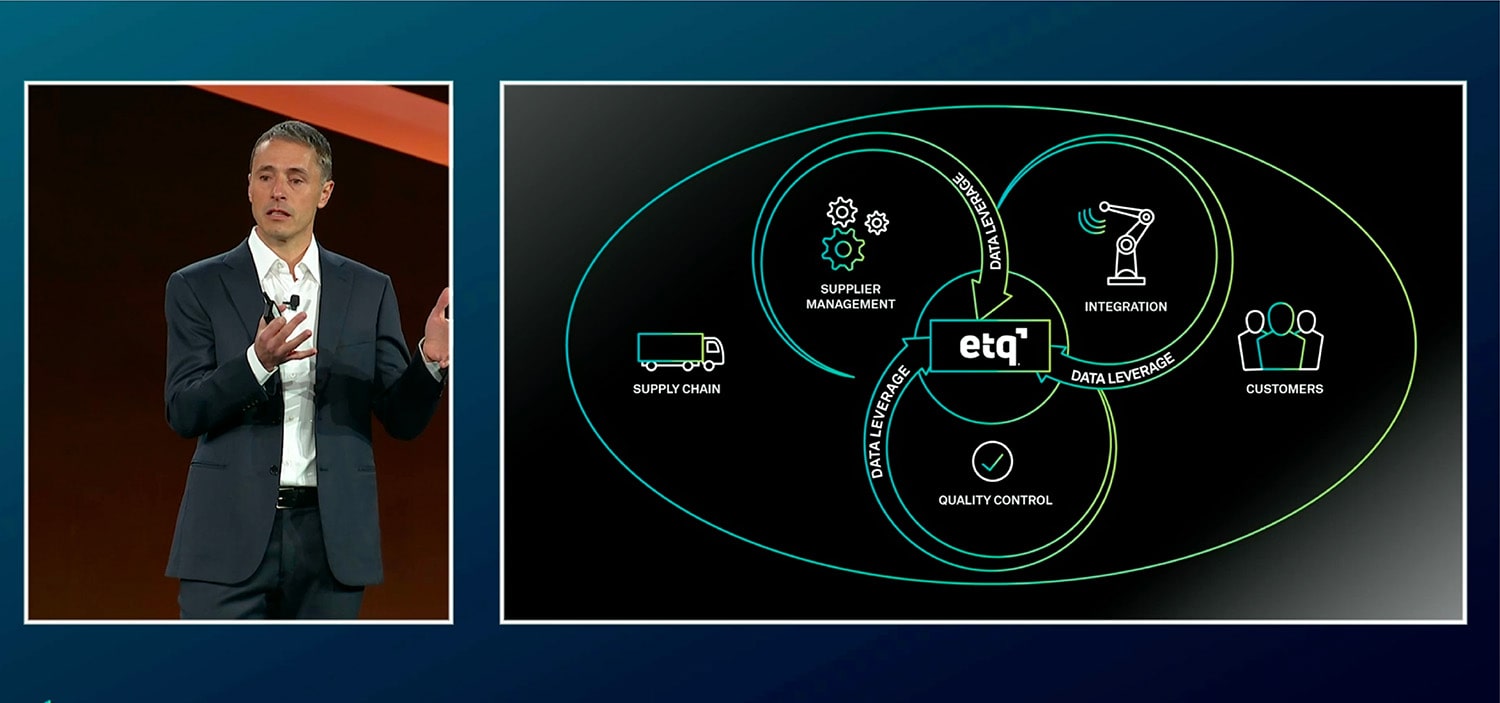

And then, of course, beyond branding, think of critical industries, think of E-Vitals, think of medical, so if you want to move from living quality as an aspiration to embedding quality through your ecosystem, ultimately, it becomes a matter of methods, communication processes, tools, data ultimately. This is why we have joined forces with ETQ a couple of months back ETQ is the best quality management system in the market today.

36:16

ETQ has a super accomplished platform called Reliance of roughly 40 applications that are centered around quality. What ETQ and Reliance provide to manufacturers today, is basically a superhighway of quality data. Quality data that gets aggregated from the enterprise stack that gets aggregated from design that correlates quality outcomes with the manufacturing process, key data, correlated to data as it gets measured in real-time; and over the future, we’re going to see more and more of these tools being capable of inspecting in real-time customer feedback. So that we can connect the experience that customers have with our products with all the processes from design to engineering that are providing those products.

And then of course, ETQ connects seamlessly across the supply chain So what we want to do is to move from having little transparency to being able to actually cross-correlate that data to be able to predict quality outcomes. This is something that ETQ already does today in the marketplace; there are more than 600 customer manufacturers that entrust ETQ with their quality processes.

38:00

Think of Trane technologies; Trane is a complex manufacturer with roughly 30 billion in market cap, 30,000 employees, and 100 plants, so countless quality processes need to be managed for which we want to have transparency. Trane rolled out ETQ across the landscape of factories and divisions, reaching staggering amounts of warranty cost reductions and scrap rate reductions rework reductions.

Think of Lumileds; I think was born as a joint venture between Philips Lighting and Agilent is a cutting-edge provider of lighting solutions for the world of consumers but also for the world of automotive, and you know how much in the world of automotive increasingly they’re going to be reliant on sensors of different types that integrated to make those vehicles more intelligent.

So we cannot clearly tolerate those application failures due to poor quality. Lumileds has implemented ETQ starting from a landscape in which quality management was a bit of an afterthought, roughly 200 applications disconnected and very siloed across multiple factories. They move from that ecosystem onto reliance, and that has triggered savings on a yearly basis in terms of operation and quality KPIs.

Think of NVIDIA; NVIDIA is a super cutting-edge developer of GPUs they work with Tesla to develop the next-generation autonomous vehicles. NVIDIA has rolled out reliance and has created open communication between themselves and their quality processes and Tesla. So that both OEMs and partners could check on quality processes and data in real terms.

So ultimately, quality is a team sport; ultimately, quality is the capability of building an ecosystem of partners that are quality minded but, of course there, are equipped with the same powerful tools.

So please, if you’re interested or intrigued by the world of quality management if you’re asking yourself how the data that your specialists in reality capture can be transformational increasingly transformational for your organization but also if you want to know how your own experience and capabilities and knowledge can be put to even better use within your organizations using these highways of quality data.