Industry 4.0 began more than a decade ago and today it encompasses digital technologies, automation, robotics, data analytics and the Internet of Things (IoT) – all playing key roles in the manufacturing enterprise. Once again, Industry 4.0 is marked by a new evolution – a shift to a digital native workforce, or the connected worker.

Empowering these frontline workers with connected tools is a topic our CTO John Taylor recently addressed in his Forbes Technology Council column.

According to John, the key to the empowerment of frontline workers is data. Consider the following:

- A plethora of data that is harvested from sensors and equipment is enabling predictive maintenance and ensuring safe and seamless operations;

- Training data is helping workers follow safe operating procedures and giving them the ability to share data that can impact safety; and

- Data is powering AI on the assembly line to identify product quality issues before they reach end users, to name a few.

For perhaps the first time, data is becoming the purview of the frontline worker.

“Organizations can achieve tangible benefits by elevating the frontline worker digital experience and empowering their frontline workforce with the technology, tools and information required for the job.” They also explain, “When frontline workers are provided a thoughtful and strategic mix of technology to perform their jobs, productivity increases on average by 22%.”

Deloitte

Armed with digital tools such as mobile apps, electronic devices, automation and AI, connected workers are not only boosting their productivity, safety and efficiency on the factory floor, but they’re also becoming empowered with the information and tools they need to make informed decisions, improve their performance and streamline manufacturing processes.

With these tools, they’re able to conduct real-time communication, access data and collaborate with other workers, machines and systems. And the future of the connected worker is just beginning to come into focus.

John described the following scenario in his article that showcases the power of connected workers. What if a worker on the factory floor discovers that lids on yogurt cups are not sealing properly? They create a report in a connected worker software platform, which automatically creates a quality event in the enterprise’s quality management system (QMS), leading to an investigation or the launch of key quality processes, such as Corrective and Preventive Action (CAPA), Supplier Corrective Action Request (SCAR), or nonconformance. Once this investigation occurs, they may identify that the supplier changed the adhesive composition on the yogurt lids. They would then automatically alert all other sites and send instructions to each factory floor to heat the lids 10 degrees higher.

Through an automatic workflow across the enterprise’s ecosystem, humans interact with technology to revolutionize manufacturing processes, drive data-enhanced decision making and enable continuous improvement of processes and products.

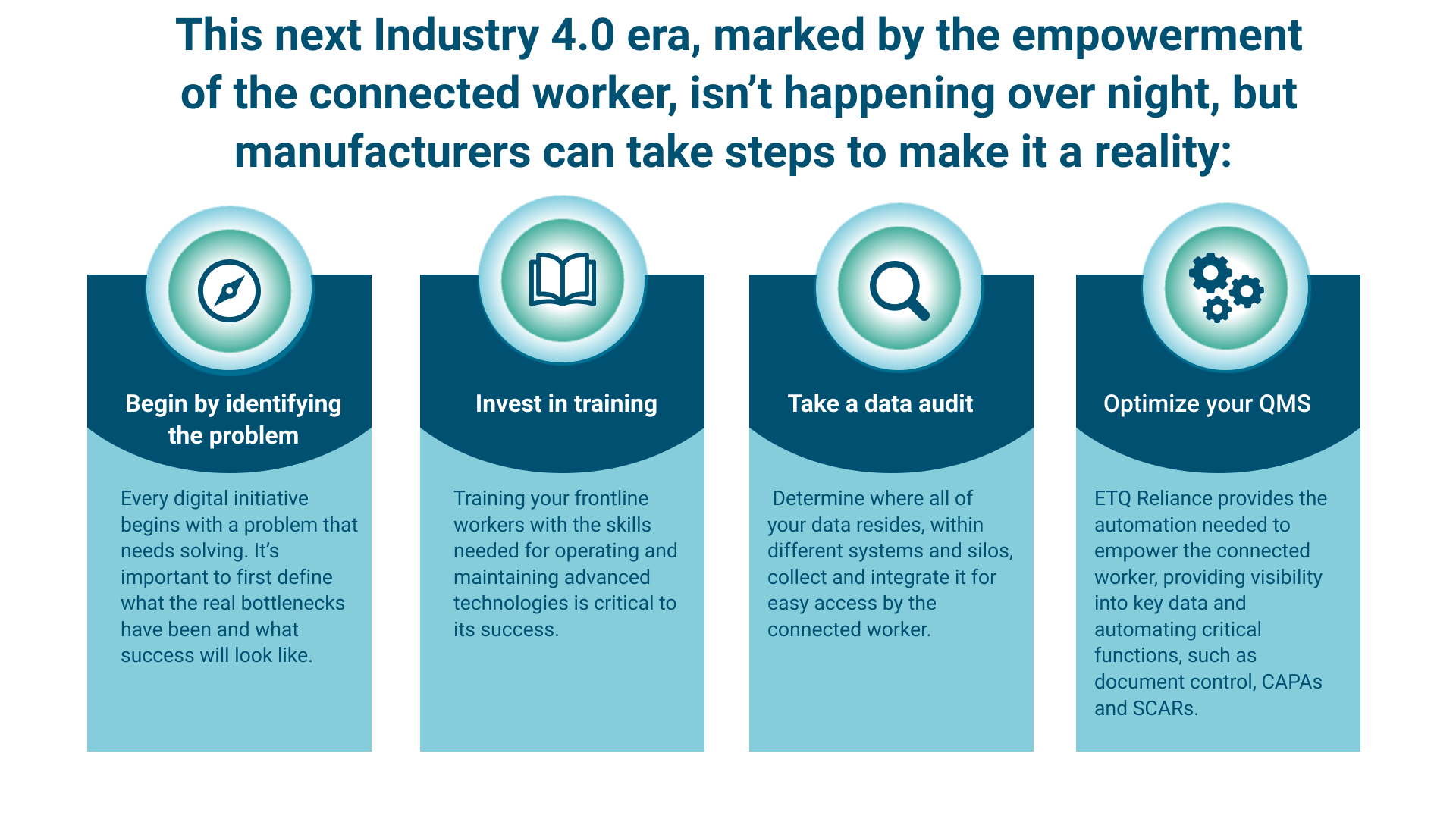

This next Industry 4.0 era, marked by the empowerment of the connected worker, isn’t happening over night, but manufacturers can take steps to make it a reality:

Begin by identifying the problem. Every digital initiative begins with a problem that needs solving. It’s important to first define what the real bottlenecks have been and what success will look like.

Invest in training. Training your frontline workers with the skills needed for operating and maintaining advanced technologies is critical to its success. It’s equally important to dispel concerns of technology taking away jobs, demonstrating that technology is actually a conduit to greater individual success.

Take a data audit. Determine where all of your data resides, within different systems and silos, collect and integrate it for easy access by the connected worker. Adopting cloud-based solutions can enable easy access to it from different locations and facilitates collaboration among teams.

Optimize your QMS: ETQ Reliance provides the automation needed to empower the connected worker, providing visibility into key data and automating critical functions, such as document control, CAPAs and SCARs.

The rise of the connected worker is empowering organizations with the insights needed to boost quality, safety, productivity and revenue – beyond the C-suite or boardroom. By focusing on the frontline worker and enabling them to make data-driven decisions, the notion of Industry 4.0 is experiencing perhaps one of its most transformative shifts to date.