Food and beverage companies perform a delicate balancing act. Their goal is to lower the overall cost of poor quality. They want to achieve this while avoiding any compromises that might lead to increased waste, product recalls, or damage to their reputation. A quality management system (QMS) can help businesses achieve that balance.

Understanding the Cost of Poor Quality

The cost of quality (CoQ) encompasses two main components. It includes the total cost of efforts to prevent quality issues. Additionally, it covers expenses incurred while dealing with quality failures. There’s a simple formula for this:

CoQ = Cost of Good Quality (CoGQ) + Cost of Poor Quality (CoPQ)

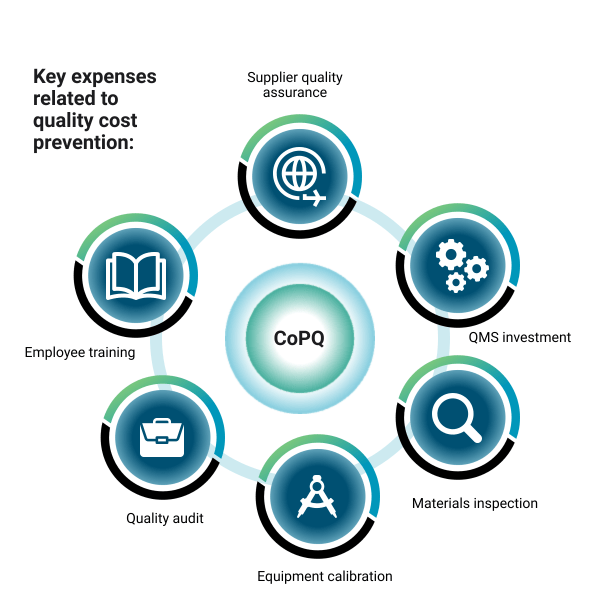

Companies must prioritize quality improvement efforts in an industry where lapses in quality can result in food safety issues and costly recalls. Neglecting these efforts could lead to major public health crises. Key expenses related to prevention and appraisal include:

- Employee training

- Supplier quality assurance

- QMS investments

- Materials inspections

- Equipment calibration

- Quality audits

Reducing the Cost of Human Error

Human error plays a significant role in CoPQ, but a QMS can help reduce employee mistakes. A QMS supports employees by:

- Enhancing employee training and tracking proficiency, ensuring employees receive the appropriate training for their location, department, and role.

- Providing real-time data and automated alerts to inform employees of potential noncompliance issues and preempt errors on the factory floor.

- Streamlining workflows, standardizing processes, and ensuring consistency across different business locations and functions.

Prioritizing Proactive Risk Management

Without a solid quality management strategy, organizations tend to be reactive, responding to problems as they occur. A reactive approach is risky, especially for food and beverage companies whose quality issues could seriously ill customers.

Businesses often get stuck reacting to problems instead of proactively preventing them. Implementing a QMS can shift this focus, letting companies use their time and resources to stop issues before they arise. Here’s how a QMS helps companies manage risk and become proactive:

- Thoughtfully placed risk tools within various processes, including audit management, play a crucial role. They help make sense of data and weed out potential problems before they can occur.

- Identifying high-risk areas helps quality specialists establish priorities and use their time efficiently.

- Industry-specific compliance monitoring keeps companies aligned with regulatory requirements, including FSMA, GMP, SQF, and HACCP.

- Centralized reporting allows businesses to make more informed, strategic decisions about quality efforts.

Enhancing Supplier Quality Management

Even when a supplier is at fault for poor quality, it still reflects poorly on your brand. When poor supplier quality drives high costs, a QMS can help by offering:

- Detailed supplier ratings to identify top-performing suppliers and suppliers who may be under-performing.

- Secure portals for efficient communication about corrective actions and swift problem resolution.

- Reporting tools that allow businesses to produce data-backed evidence during supplier negotiations.

One national fast-food chain uses a QMS to centralize and automate its vendor approval system. This approach increases visibility and prevents requests from languishing in email inboxes. The QMS helped the company speed up the vendor approval process and quickly bring new products to market — all while enhancing quality.

Your Path to Cost-Effective Quality

A food and beverage business’s ultimate goal should be to find ways to reduce the cost of quality. Simultaneously, they should focus on improving the overall quality of the product. A quality management system provides quality specialists and business leaders with the tools needed to do this. Connecting a QMS across all business areas provides a clear picture of ongoing quality initiatives. This transparency reveals opportunities to optimize quality efforts in every department.

A QMS identifies potential issues early in the manufacturing process. This identification reduces the likelihood of defects further down the line. Defects become more costly at this stage due to waste, recalls, and returns. Additionally, they can damage the brand’s reputation.

To learn more about how a QMS can help reduce the cost of poor quality, contact ETQ today.