Every root cause analysis (RCA) your organization completes represents a potential cost-saving and revenue-generating opportunity. Unfortunately, many manufacturers never capitalize on it because they file the information away, close the problem and never revisit it.

Take the following as an example:

- A packaging line at one plant discovers that a specific supplier batch caused contamination

- They fix it, document the RCA, close the corrective action

- Six months later, Plant B experiences the exact same issue, maybe even with the same supplier

- The company eats the duplication costs, loses out on weeks of productivity and risks their margins to potentially angry customers and returns

When RCA is treated solely as an incident report instead of a report and a learning asset, companies lose out on millions.

Why RCAs Stay Local (And How to Fix It)

Before we talk about solutions, let’s acknowledge why RCA findings don’t spread naturally. There are three main reasons: Time, systems and processes.

- No time: Quality teams don’t have bandwidth to manually check if an RCA applies elsewhere.

- No system: There’s no mechanism for cross-plant review.

- No processes: Revisiting RCA findings isn’t part of a review process.

These aren’t failures of your people. They’re failures of system design. Here’s how to redesign the system.

1. Shift From “Fix the Incident” to “Fix the Portfolio”

Change how you think about RCAs. Instead of thinking about them as individual RCAs, think about them as portfolios.

In many RCA approaches, the process looks like this:

- Defect occurs

- RCA completed

- Local corrective action completed

- Report filed/emailed

- Case closed

This approach requires people to recall issues from memory or at least to remember to look up whether there was a problem before. Many manufacturers are facing staffing issues and they’re using workers and the knowledge they have.

With a portfolio approach, you can combat this issue a bit. Here’s how to change your process.

- Defect occurs

- RCA completed

- Alerts sent

- Past RCAs reviewed for trends

- Scoping questions asked:

- Which products, lines or plants could this effect?

- Report filed/emailed

- Case closed, readily available for review

This approach can save hundreds of thousands of dollars, if not millions.

Rheem developed a custom system called the Reliance Development Life Cycle (RDLC) using ETQ Reliance®. When they applied this system across three projects in the first year, Rheem saved an estimated 3,000 hours, or roughly $940,000 — a 650% return on their investment.

2. Make RCA Outcomes Visible to Finance, Not Just Quality

Quality managers track corrective actions. Executives track money.

The disconnect is why RCAs feel like compliance overhead instead of strategic value. Bridge the gap by translating quality outcomes into financial outcomes.

Start simple:

For every RCA you define as significant, estimate the:

- Cost of the incident (scrap, rework, expedited shipping, customer complaints)

- Cost of recurrence (what would it cost if this happened again?)

- Cost avoidance from the fix (recurrence cost × likelihood × time period)

You don’t need precision here. Conservative estimates are fine. The goal is to make the value visible, not to create busy work for quality teams.

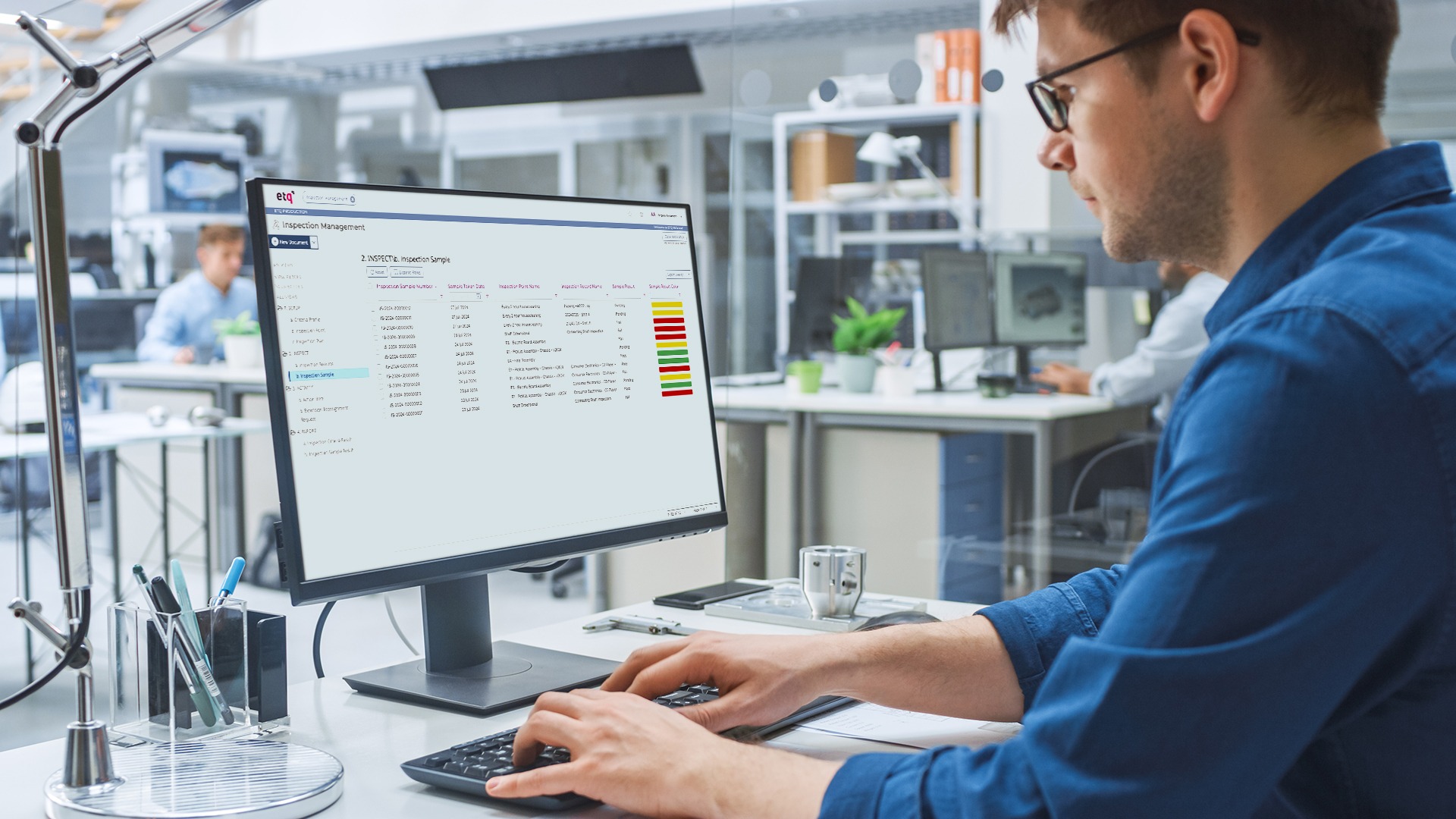

Then track patterns:

Create a quarterly review of RCA financial impact:

- Top 10 RCAs by cost avoidance

- Total cost of quality recovered through RCAs

- Cycle time from RCA initiation to full deployment

- Percentage of RCAs deployed beyond local scope

This approach changes the process from one that’s about reporting to one that’s about thinking about how findings impact your organization. When a plant manager sees that sharing an RCA created $400K in value for the enterprise, the incentive structure shifts.

3. Close the Training Loop Automatically

Another common failure point is when an RCA identifies operator error as a contributing factor. The corrective action is to “retrain affected staff.” Six months later, an audit reveals the retraining never happened because:

- Quality opened a ticket for Training

- Training said they needed an updated SOP first

- Engineering said they were too busy to revise the SOP

- The corrective action sat in “pending” status until everyone forgot about it

This is a time and process issue. Sometimes organizations will try to fix this by adding another manual handoff to the process. But if manual processes are the problem in the first place, adding another isn’t going to help.

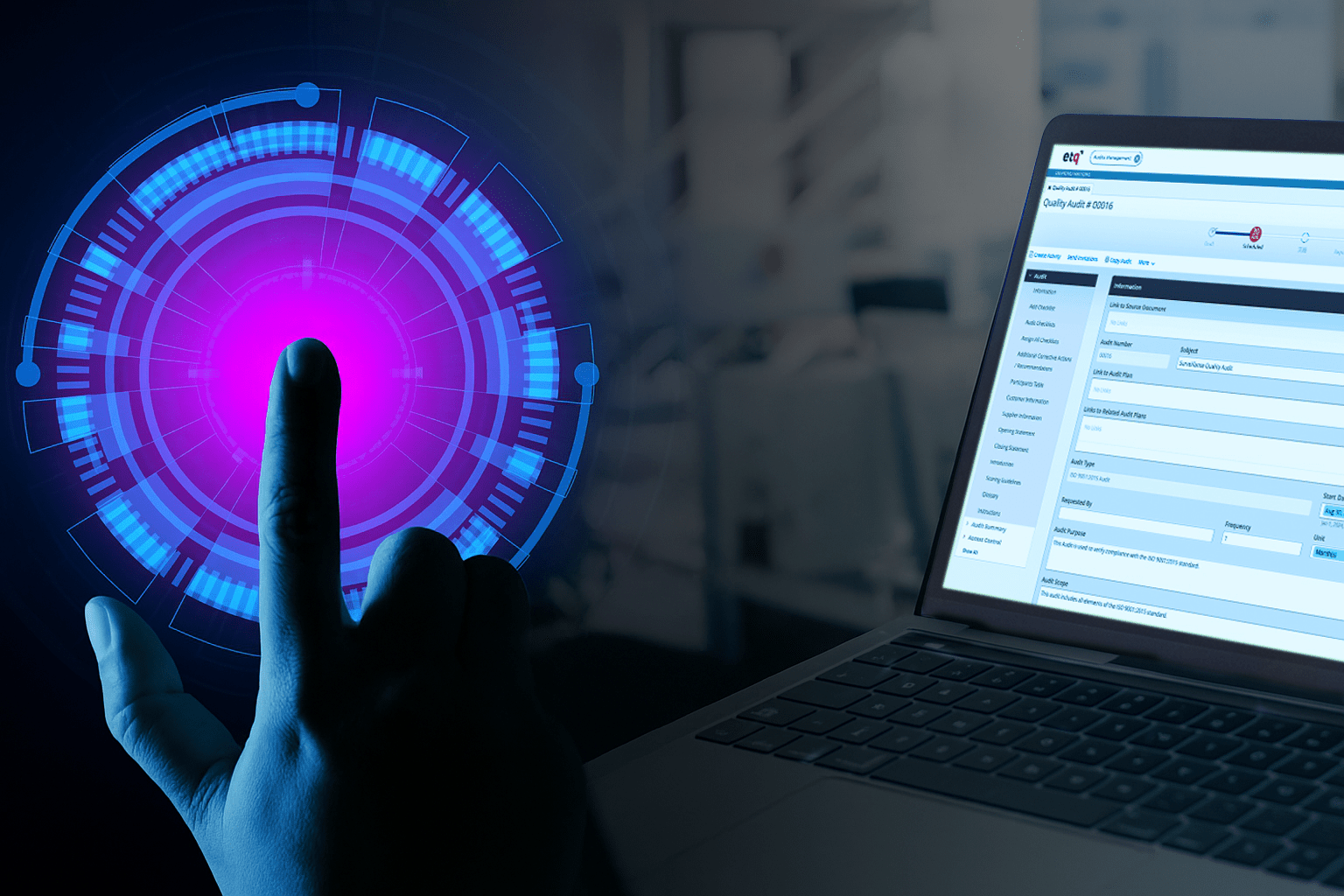

Instead, automate it so that when an RCA identifies a training gap:

- The system auto-generates a training update requirement

- The updated procedure or control is drafted during the RCA process (not after)

- Affected personnel are auto-flagged for retraining based on their assigned roles

- The corrective action can’t close until training records show completion

If you remove the need for someone to remember to do the follow-up, then you remove some of the points where the process can fail. Now, your RCA findings can lead to continuous improvement.

4. Look for Patterns, Not Just Incidents

Individual RCAs tell you what broke. RCA clusters tell you what’s breaking your system.

By implementing some of the previous processes, you should get some time back in your day. Use it to reserve at least two hours each quarter to review RCA patterns with your quality and operations leaders. Don’t review individual cases. Review categories:

- Supplier issues: Are 30% of your RCAs tracing back to 3 suppliers? Time for supplier development or alternate sourcing.

- Training gaps: If 40% of RCAs involve procedure non-compliance, you don’t have 40 procedure problems – you have 1 training system problem.

- Equipment reliability: Clustering by equipment type reveals where preventive maintenance isn’t preventing anything.

- New product introduction: Pattern of RCAs immediately after launches? Your NPI process needs work.

For each cluster, ask:

- What’s the aggregate financial impact?

- What systemic control could prevent the whole category? (e.g., supplier audits, automation, poka-yoke design)

- What does that control cost vs. the recurring cost of incidents?

- Decision: invest, defer or accept the risk?

This is where your root cause analyses become strategy. Your RCAs move from independent fires that need to be put out into a continuous process that improves your quality.

5. Incentivize Cross-Functional Learning

Of course, culture doesn’t change because you tell people to collaborate. It changes when you reward collaboration.

If you implement these changes, there’s a chance that your organization becomes so good at stopping problems that you begin to have zero problems.

Something similar happened to Owen Mumford, a medical device manufacturer. They implemented a systematic approach to RCA deployment and continuous improvement. Afterward, when the FDA inspect all four of their manufacturing sites from 2015 onward, they issued zero 483s. Additionally, their CAPA across UK sites dropped 45% from 2016 to 2021, and nonconformance reports fell 50% in the same period.

The results are amazing. However, doing this requires complete buy-in. You also need to make sure you incentivize these process to avoid complacency from creeping in.

Here are some ways to incentivize the new processes so that both current and new employees understand their importance.

For plant managers:

- Add “RCA deployment support” as a weighted KPI (even 5-10% matters)

- Measure: “How many RCAs did your plant generate that were deployed elsewhere?” and “How many RCAs from other plants did you implement?” and “How many potential issues did you prevent from ever developing?”

For quality teams:

- Track “RCA cycle time to full deployment” not just “time to close corrective action”

- Celebrate “RCA of the quarter” that had the highest scaled ROI

For executives:

- Make cross-plant RCA sharing a standing agenda item in operations reviews

- When plants share a winning RCA, recognize both the originator AND the deployer

Small symbolic changes in measurement drive large behavioral changes in practice.

Where to Start: The Monday Morning Action

This all sounds great in a blog post. But you’re busy, your teams are stretched, and adding new initiatives feels impossible.

Here’s the smallest viable starting point:

This week, pick your 3 most recent significant RCAs. For each one, spend 15 minutes with your quality and ops leaders asking:

- “Could this defect mechanism occur anywhere else in our operations?”

- “If yes, what would it cost to deploy the fix to those locations?”

- “What would it cost if the problem occurred there before we deployed the fix?”

Do the math. If the ROI is compelling, assign an owner and a deadline for deployment.

That’s it. You just turned 3 compliance documents into strategic assets.

Do it again next month. Then build the system around the behavior that’s working.

The Bottom Line

You’re already performing RCAs, but you can use them to do more than put out fires. With some changes, you can turn them into continuous improvement and extract full value from them.

If you’re struggling to get the information you need to implement these changes, check your processes. Replace manual processes where you can and connect disparate data sources as needed. Automate as much of the tedious work as possible, including reporting, alerting and training.

And, if you’d like a little help implementing this, we’re always here to help. Reach out to us and let us know what you’re envisioning, and we’ll gladly assist you along your journey.